Compared with step 3 (Finite Element Analysis) the profile stress analysis calculates very quick and can be used during the design process. On the other hand, FEA calculates most precisely not only stress and strain but also the profile shape.

| Profile Stress Analysis (PSA) | <-- 14 15 16 17 18 --> |

|

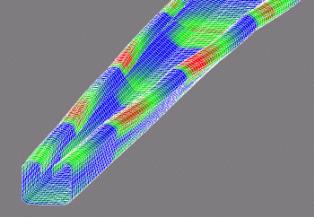

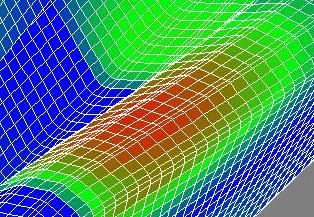

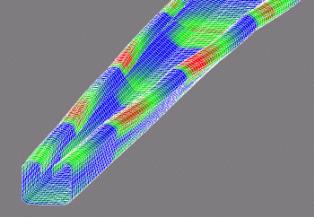

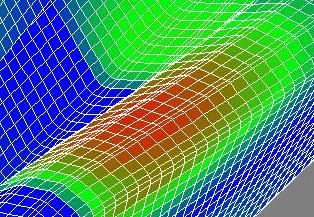

Profile Stress Analysis (PSA) is the second step of the three steps quality management concept. The sheet surface is divided in small rectangular shell segments. The segment width and with it the precision of calculation can be defined by the user. Critical areas like the bending zones can be calculated with higher resolution. While running through the roll forming machine, the rectangles are formed to general quadrilaterals. From lengthening or shortening of the edges the expected strain and from it the stress can be derived. The stress related to the yield stress of the material is assigned to a color in the range between blue (0%), green (50%) and red (100%). In the 3D model critical areas can be detected by red colored shell segments. The designer can use the mouse wheel to rotate and zoom the model to examine any detail. The profile stress analysis is an integrated feature of the software PROFIL and works without FEA (Finite Element Analysis), this means the results are available after key-stroke immediately. | |

|

Compared with step 1 (stress of band edge) the profile stress analysis has the advantage that the longitudinal stress is calculated not only at the band edge but in the whole profile cross section. This is very important if maximum stress is not at the band edge, e.g. if folded edges are bent up.

Compared with step 3 (Finite Element Analysis) the profile stress analysis calculates very quick and can be used during the design process. On the other hand, FEA calculates most precisely not only stress and strain but also the profile shape. |